Product Description

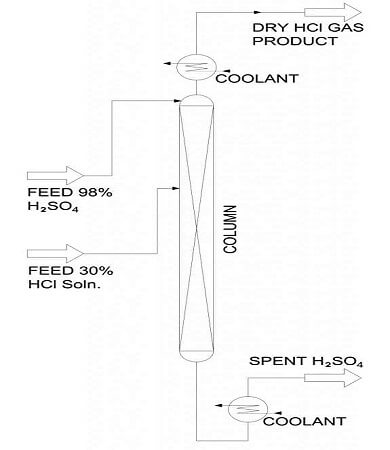

The plant produces dry HCl gas by the process of distillation of 30% hydrochloric acid with concentrated sulphuric acid as entrainer. Feed Sulphuric acid is fed from top to the packed column and feed 30% hydrochloric acid is also fed to the column. Both the acid flow concurrently. HCl gas is generated by mixing of the two liquid acid feeds. The top portion of the packed column acts as a drying zone for the product HCl gas.

Condenser / Cooler is provided on top of a column to cool the outgoing HCl gas. Suitable drying section removes final traces of moisture from outgoing HCl gas. The bottom product from the plant is spent Sulphuric acid with 70% strength (with 1-1.5% HCl content). It is cooled in a heat exchanger prior to discharge.

All the wetted parts of the system are fabricated from corrosion resistant materials (Glass and PTFE).

Salient Features

- Low capital cost

- Simple process

- Very compact design

- Medium operating cost

- Spent Sulphuric acid (approx 70% w/w) with 1% HCl content as a by-product

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?