Product Description

Ablaze manufacture and supplies a high-quality range of Fractional Distillation Unit. This product is highly recognized and demanded due to its special character like resistance against split, abrasion, high thermal and chemical stability. The offered product is tested on various quality parameters in adverse condition to ensure its reliability and durability. We are providing this Fractional Distillation Plant up to 500 Liter

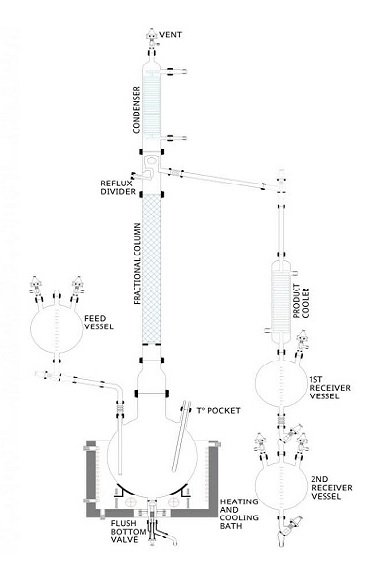

This is basically a compact fractional distillation unit of the batch type in which the reboiler consists of a vessel placed in a heating bath and above with a packed base. The vapors are condensed from the top and can be regulated as needed.

The top material is sub-cooled and stored in receivers. A drain valve eventually drains the bottom liquid from the reboiler. The systems are available in 50 Liter, 100 Liter, 200 Liter, 300 Liter & 500 liter vessel sizes.

Fractional distillation is the process of taking a chemical mixture and using heat to separate the different components of the mixture. It is a special type of Fractional distillation in which two miscible liquids having different boiling points but closed to each other are separated by fractionating column.

In this process, the mixture is boiled in a round bottom flask, and the vapors of the boiling solution passes along the fractionating column. The temperature of the column is coolest at the top and gradually increases down as at the bottom it is attached with heating media.

Now, the components with higher boiling points condense on the column and hence after condensing they return to the solution. and the components with lower boiling points further pass through the column and are collected as they are more unstable.

Salient Features

- Reactor up to 500-liter capacity

- ” ZERO” Hold Up with Temperature Sensing Valve

- Quick Closer for the addition of Solid

- Visual monitoring of the process, improving safety and reliability of production

- Dual functional heating & cooling oil/water bath

- Can be designed for the batch as well as continuous operations

- All wetted parts are made from Borosilicate Glass, and PTFE, providing universal corrosion resistance

- Low CAPEX, and easy to maintain

- Zero Hold-up in reflux divider.

Dimension Table

| DESCRIPTION | AFDU 50 | AFDU 100 | AFDU 200 | AFDU 500 | |

|---|---|---|---|---|---|

| Reactor Nominal Capacity | ltr. | 50 | 100 | 200 | 500 |

| Heat Exchanger (Exchange Surface) | m2 | 0.5 | 1.5 | 2.5 | 5 |

| Bath Heather Capacity | kW | 6 | 8 | 12 | 18 |

| Vessel Design Pressure | bar(g) | -1 to +6 | -1 to +0.5 | -1 to 0.4 | -1 to +0.3 |

| Plant Working Temperature | ºC | -20 to +180 | -20 to +180 | -20 to +180 | -20 to +180 |

| Plant Design Temperature | ºC | -25 to +200 | -25 to +200 | -25 to +200 | -25 to +200 |

| Plant Working Pressure | bar(g) | +0.5 | +0.4 | +0.3 | +0.2 |

| Feed Vessel | No. × ltr. | 1 × 5 | 1 × 10 | 1 × 20 | 1 × 50 |

| Receiver Vessel | No. × ltr. | 2 × 5 | 2 × 10 | 2 × 20 | 2 × 50 |

| Vapour Line Column | DN | 50 | 100 | 150 | 225 |

| Rupture Disc | bar(g) | 0.5 | 0.5 | 0.5 | 0.5 |

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?