Kilo Lab & Glass Reactor

A pioneer and a global leader in designing, manufacturing, and supplying the Kilo Lab Glass Reactor and Pilot Plants, Ablaze Export Pvt. Ltd. is here to serve you better with better quality industrial equipment. We manufacture our products using all premium quality materials such as Borosilicate glass, which is used in designing our Kilo Lab Glass Reactor along with the overhead condensers and the heat transfer systems having attached process controls.

We manufacture and supply customized Kilo Labs designed with all the necessary and cleverly accessible fill-up points, collecting points, and sampling points to gain significant control of all the processes in the Kilo Lab. We manufacture the glass reactors so transparent that you can have an explicit vision of the entire process and can observe, record data, and analyze the process in real-time for the optimization as per the requirement.

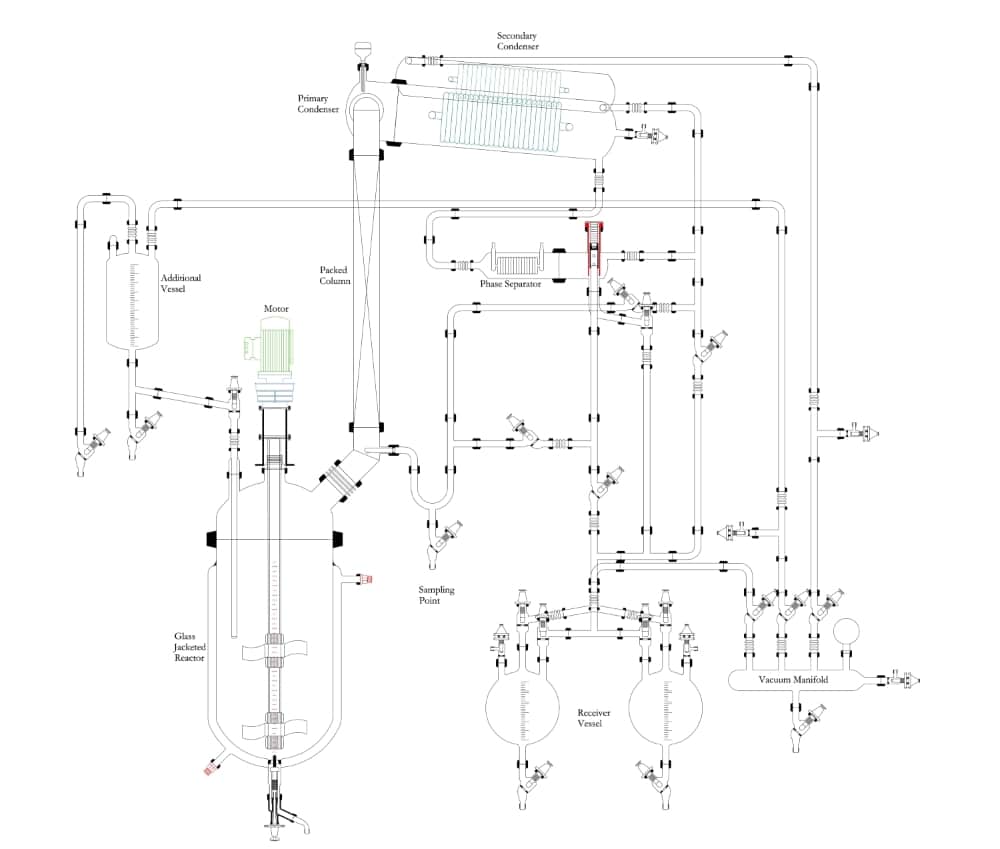

Ablaze Export Pvt. Ltd. offers you a wide range of customized distillation systems assembled with the Jacketed Glass Reactor for Kilo Lab. It includes the condensers, vapor column, dean stark, reflux provision, add on and receiver vessels, phase separator, along with various valves placed at an appropriate distance, and all the other supporting metal structures. All our units are supported by the TCU (Thermal Control Unit) that helps the circulation process in the Jacketed reactors. We also manufacture and offer a triple wall glass reactor for the kilo labs and pilot plant that has 50 liters of working capacity.

Pertinent Features of Kilo Lab Glass Reactor

Fundamental Objective

The prime objective of the Kilo Lab Glass Reactor is to produce a simulation for flexibility and agility to guide a compelling portfolio of a resulting potential product along with maintaining the standard Environmental Health and Safety (EHS) Policy and the product quality as well.

Kilo Lab is known to help in manufacturing the small number of Products from the active pharmaceutical elements and also in evaluating the production as well as the development process before starting the commercialization plant.

Kilo labs support the discovery of the fact if the promising product is extensible in the Kilo lab or not and if it can save your business from high expenses and more research time.

We do understand the fact that constructing and running a developing process in Kilo Lab only once will never assure that the product with the same potential and qualities will be created in the cGMP manufacturing process.

That is why we are in a constant race of developing and designing Kilo Lab Glass Reactor in such a manner that you will be able to test your new processes several times even before shifting them to the development stage in the pilot plant.

Dimension Table

| DESCRIPTION | UNIT | AGR 20 | AGR 50 | AGR 100 | AGR 200 |

|---|---|---|---|---|---|

| Reactor Nominal Capacity | ltr | 20 | 50 | 100 | 200 |

| Heat Exchanger (Exchange Surface) | m2 | 0.5 | 1.0 | 1.5 | 2.5 |

| Jacket Design Pressure | bar(g) | -1 to +0.5 | -1 to +0.5 | -1 to +0.5 | -1 to +0.4 |

| Vessel Design Pressure | bar(g) | -1 to +1 | -1 to +0.7 | -1 to +0.5 | -1 to +0.4 |

| Plant Working Temperature | ºC | -50 to +180 | -50 to +180 | -50 to +180 | -50 to +180 |

| Plant Design Temperature | ºC | -60 to +200 | -60 to +200 | -60 to +200 | -60 to +200 |

| Plant Working Pressure | bar(g) | +0.8 | +0.6 | +0.4 | +0.3 |

| Feed Vessel | ltr. | 10 | 20 | 50 | 100 |

| Receiver Vessel | No. x ltr. | 2 × 10 | 2 × 20 | 2 × 50 | 2 × 100 |

| Vapour Line Column | DN | 50 | 80 | 100 | 100 |

| Rupture Disc | bar(g) | 0.5 | 0.5 | 0.5 | 0.5 |

| Stirrer Speed | rpm | 20 to 250 | 20 to 250 | 20 to 250 | 20 to 250 |

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?