Industrial Glassware

Mainly all the Industrial Glassware is manufactured from borosilicate glass 3.3. It is the most commonly accepted material used to build the whole process system that can be used in various industries such as the chemical industry, dyestuff industry, food industry, pharmaceutical industry, and petrochemical industries. -6 is the answer as the coefficient of the linear expansion of (3.3 ± 0.1) x 10 K, which is significantly lower among the other industrial glass available in the market. The Borosilicate glass expands less, and hence, it’s tensile stresses on the wall are recorded much less during the heating process, resulting in making it capable of withstanding a bigger thermal shock and increasing the maximum working pressure capacity upon a given functional temperature. The Borosilicate glass is complemented by using corrosion-resistant materials like ceramics and PTFE.

We Manufacture

- Glass Pipeline Components

- Glass Valves

- Glass Vessels And Stirrers

- Heat Exchangers

- Column Components

- Coupling And Gaskets

- Sight Glass

- Structure Parts

Resistance to Chemicals

Borosilicate glass is used to produce the equipment and vessels and is categorized as a crucial part of Industrial Glassware. It is highly resistant to relatively all the substances other than phosphoric acid, hydrofluoric acid, and hot strong caustic solutions. Out of these substances, hydrofluoric acid poses a serious threat, and the corrosion can occur even if the solution contains only a small amount. Caustic solutions and Phosphoric acid can only cause corrosion at higher temperature levels. Caustic solutions that are concentrated up to 30% can be safely handled at normal, as well as ambient temperatures.

Special Properties of Borosilicate Glass 3.3

Borosilicate Glass 3.3 is the most commonly used material across the world in various industries such as pharmaceutical and chemical industries and also in many other areas. It has a wide acceptance, which is essentially made possible because of its thermal and chemical properties. Below mentioned are some of the special properties.

-

- It has a smooth and pore-free surface

- It is transparent, and you can see through the vessel clearly

- It has phenomenal corrosion-resistant properties

- It has physiological suitability properties

- It is non-flammable

- It has catalytic inertness

- It is neutral in taste and smell.

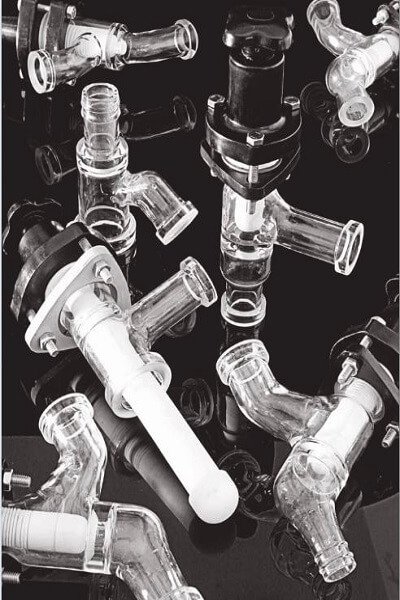

Glass Pipeline Components in Industrial Glassware

The Glass Pipeline Components made from Borosilicate Glass 3.3 are widely accepted in the chemical industry, pharmaceutical industry, and also in all the other allied industries, which are into the production of food and drugs, electroplating, and dye production industry. The Borosilicate Glass 3.3 is widely popular because of its peculiar properties such as follows

-

- Its smooth surface allows you to clean and sterilize it with utmost ease, and it also prevents the solids from building up on the inner walls.

- It has universal corrosion-resistant properties that give it a long life and guarantees the best service and minimum maintenance.

- The transparency of the material and the equipment permits you to have clear visual monitoring.

- It has inert properties that lower the contamination risk.

Glass Valves in Industrial Glassware

Glass valves are commonly used in the chemical industries, pharmaceutical industries as well as the allied industries. The Glass valves are considered a crucial part of any process system or plant that has a variety of applications, such as pressure relief, flow controls, and filtration. Borosilicate glass 3.3 with PTFE is used in manufacturing the Glass Valves. Hence, the Glass valves have fully corrosion-resistant properties and are chemically inert because of their glass body.

Entire range of glass valves manufactured by Ablaze Export Pvt. Ltd. are,

- Line Valve

- Drain Valve

- Angle Valve

- Vent Valve

- Vent Vacuum Valve

- Non-return Ball Type Valve

- Bottom Outlet Valve

- Adjustable Overflow Valve

Glass Vessels And Stirrers in Industrial Glassware

Plenty of glass plant installations have vessels that find universal applications such as re-boilers, reactors, separators, and receivers. The Glass vessels are easily available in cylindrical and spherical shapes, having 5 to 500-liter capacity. All the vessels are built with an outlet nozzle at the bottom, which allows you to select your valve from the variety of valves. Both Cylindrical, as well as Spherical vessels, can be delivered on the request of a special order.

ablaze vessels & stirrers provide best solution for all requirements encountered in production processes because of wide range of vessels available. Vessels are essential components of many units & plants. The vessels can be combined with various components as stirrers, stirrer drive, vessel covers & heat exchangers to construct wide variety of stirred units & reaction systems. These vessels find universal application as reactors, receivers, reboilers, Cyclone separators, Liquid extractors in the chemical industry.

Borosilicate glass vessels are available for major Unit Operation and Unit processes. Customised Solutions are also Availble. Please ask our Glass Process engineer for Fixing exact suitable glass equipment. Please find different configuration and options available in Pilot Plant Flyer.

Heat Exchangers in Industrial Glassware

The Coil type heat exchangers are essentially used as the coolers or condensers. However, you can use them for the heat transfer process between the gases and the liquids. It is designed to have a coil battery welded to its jacket, which makes it a single piece unit. It can withstand the maximum pressure of 2.7 bar gauge.

Ablaze heat exchangers provide the optimum solution for every requirement encountered in practice because of the wide range of types available. Due to its very smooth surface, it has comparable heat transfer performance with other MOC.

These items are widely used in the chemical, pharmaceutical and allied industries together with other applications such as food and drink production, dye works and Electroplating. Glass Heat exchangers are available in major two types Shell and Coil and Shell and Tube Heat. Both the Heat exchangers are used in Condensation, Heating Cooling, Evaporation and as reboilers.

Column Components in Industrial Glassware

The Glass Column Components are exclusively used for the applications of the chemical industry, pharmaceutical industry as well as the allied industries along with the other applications like food production, drink production, dye manufacturing works, and electroplating.

The Glass Column Components are widely accepted because of the exceptional properties of PTFE and borosilicate glass 3.3, as it is clinically approved and proven material that can be used for the construction of the pressure vessels.

Glass column and components are available up to 600 DN Diameter.

Couplings And Gaskets in Industrial Glassware

Couplings are used to join the glass process plants as well as the pipeline components with the other metal apparatus. The full coupling process includes two inserts, two flanges, and an essential number of nuts & bolts to join them.

The couplings that are designed to use with the glass process systems and the components have two major points to be considered as follows.

-

- Ensuring the bolt load applied is enough to seal it effectively without inducing any undue stress on the glass.

- Must be completely trustworthy to serve under any service condition.

Sight Glass in Industrial Glassware

The sight glass is nothing but a glass device that is used to inspect the linear flow of several fluids. The Sight glass permits the visibility between all types of non-transparent pipelines to examine the liquid flow.

It can be used in both the vertical as well as horizontal pipelines. The Sight glass is designed in such a way that you can take a full view from any angle.

SALIENT FEATURES

- It can be used both in horizontal as well as vertical installations. All contact parts are made of Borosilciate glass & PTFE.

- It provides 360 viewing of material flow through a line, which saves time & energy. The M.O.C of frame available in MS, SS304/SS316 , PP & HDPE.

- Standard flanges drilling as per ANS116.5, ASA150 . Other drilling standard as per BS10 Table D, E and F is also available upon request.

Structure Parts in Industrial Glassware

The Glass plant, as well as all the equipment, is backed in a rectangular tubular structure. This tubular structure subsists of the galvanized tubing of mild steel along with the cast iron fittings, as described in the catalog. Such a design provides you enough flexibility for further modifications.

S.S powder coated tubings and structure parts can also be supplied on request basis.

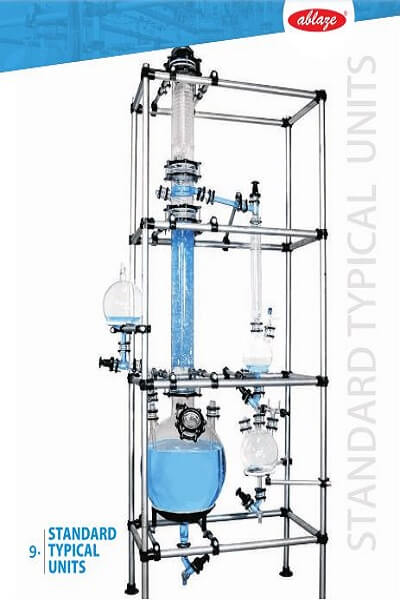

Standard Typical Units

Ablaze Export Pvt Ltd provides a wide variety of Glass Pilot Plants / Standard Traditional Glass Units, taking into consideration various operating conditions and operations. The Glass Pilot plants are used to scale up and scale down the process built at Kilolab to commercialize the process.

Standard Units deliver separate or in combination

- Double & Triple walled Glass Reactors and distillation set up over.

- Cylindrical -Spherical Glass Reactor and various Distillation set up considering Operating parameters

- Liquid Extraction Unit

- Solid-Liquid Extraction Unit

- Gas-Liquid Absorption unit

- Continuous Reactors like CSTR- PFR-Falling Film Reactor in Glass

- Various function Distillation / Fractional / Reaction Glass Units

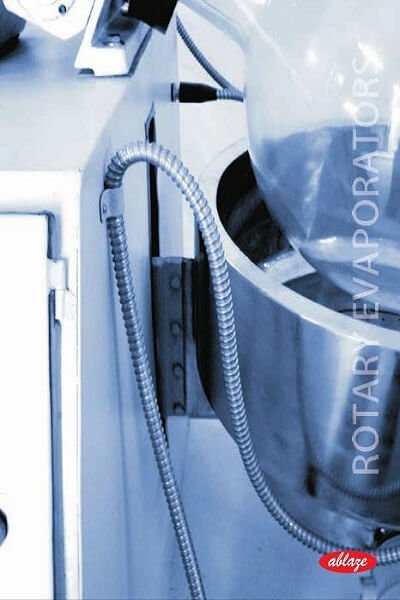

Rotary Evaporator

Ablaze is a leading Rotary Evaporator Manufacturer and Supplier, we offer a large capacity commercial rotary vacuum evaporator. The Ablaze Rotary Evaporator system operates under conditions of vacuum or atmosphere. The most common form in research is the 1 Liter to 5 Liter bench-top model, whereas, in industrial chemical operations, large-scale rotary evaporator (10L to 20 Liter and 50 Liter, 100 Liter to 200 Liter) models are used in pilot plants.

Ablaze’s series of Rotary film Evaporators are designed for Pilot and industrial scale evaporation applications. Exclusive use of superior quality Borosilicate 3.3 glass and PTFE for all components coming in contact with product ensures complete chemical resistance against almost all mediums. It is primarily used for distillation of heat sensitive and volatile components, owing to its unique construction. It can operate under full vacuum and is an essential equipment in the chemical and pharmaceutical industries.

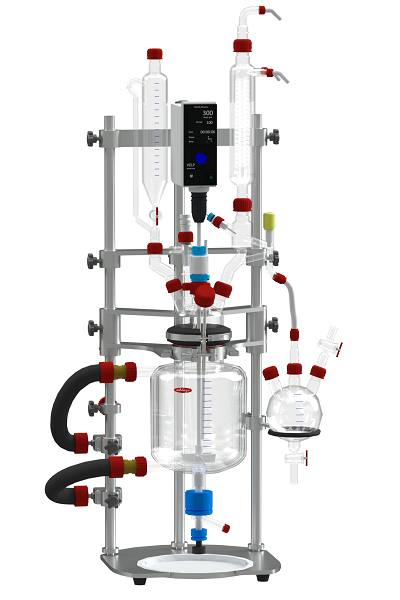

Lab Glass Reactor- Bench Top Model

One of Everything - Platform Cultivation Glass Vessel For all types of Lab Reactors.

Lab glass reactors are the greatest systems for optimizing and reproducing chemical reactions, mixing, dispersing, and homogenizing processes on a laboratory scale.

Laboratory glass reactors widely accepted as Lab Glass Reactors are known to allow you to have a clear view of the processing of the chemical reactions happening inside the reactor.

Lab glass reactors work perfectly with the given atmospheric pressures as well as the vacuum and have significant corrosion-resistant qualities. To get a higher level of productivity, a considerable amount of accuracy, and complete reproducibility.

Glass Lab Reactor with Distillation Setup

One of Everything - Platform Cultivation Glass Vessel For all types of Lab Reactors.

Lab glass reactors are the greatest systems for optimizing and reproducing chemical reactions, mixing, dispersing, and homogenizing processes on a laboratory scale.

Laboratory glass reactors widely accepted as Lab Glass Reactors are known to allow you to have a clear view of the processing of the chemical reactions happening inside the reactor.

Lab glass reactors work perfectly with the given atmospheric pressures as well as the vacuum and have significant corrosion-resistant qualities. To get a higher level of productivity, a considerable amount of accuracy, and complete reproducibility.

Glass Pilot Plant

Enhanced by huge industrial experience, we were able to produce, export, and supply a wide variety of Glass Pilot Plants. Such pilot plants are extremely important in the chemical industry.

The pilot plants offered are planned under the proper control of our expert professionals. Provided pilot plants are highly certified for their abundant aspects of efficiency in the industry.

High Pressure Glass Reactor

One of Everything - Platform Cultivation Glass Vessel For all types of Lab Reactors.

Ablaze successfully designed and produced High Pressure Glass Reactors for use on a laboratory scale. Scale-up experiments also involve the application of high pressure, and this is now possible with the other additional benefits of a glass reactor. High-pressure glass reactors are built with corrosion-resistant materials that ensure high resistance to acids while allowing reactions under pressure. The magnetic stirrer drive ensures adequate mixing and stirring of the process media, as well as excellent heat transfer.

The advanced High Pressure Lab Reactors produced by Ablaze are safe, efficient, easy to operate, and offer the interchangeability advantage. The key highlights of the product are the use of top quality raw material combined with modular and highly durable configuration options.

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?