Product Description

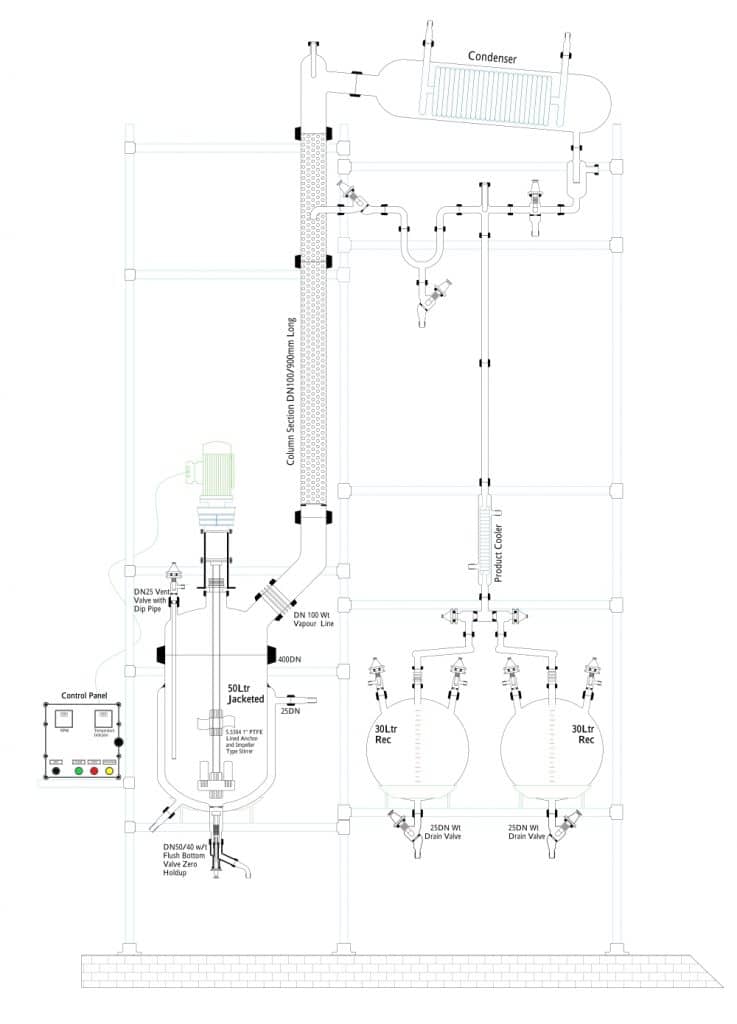

The combination of Glass Reactor with Rectification Column (borosilicate glass 3.3 distillation attachments) is an attractive approach that has been used effectively in the chemical and pharmaceutical industries.

In general, there is an important position in the manufacture of highly refined and highly pure products such as fine chemicals, plant protection agents, vitamins and pharmaceuticals, metal-free and highly corrosion-resistant material.

Best Manufacturer, Supplier & Exporter of Glass Reactor with Rectification Column, providing top notch after sales services to our clients with 100% satisfaction.

The working theory of the laboratory rectification tower: fluid mixing by partial gasification and condensation for several periods, as the various components have different instability characteristics, so that they can achieve the objective of mixture separation.

The rectifying glass reactor is famous for cleaning spices, intermediate pharmaceutical, new material, etc. For practice, the “reaction” and “distillation” processes are often sequentially performed to ensure that the initial materials react to the target products within the same equipment.

Key Features

- Integrated stainless steel tube, mobile frame structure, reaction vessel cover with 5 necks for re-fluxing, liquid feeding, temperature measurement, etc.

- Borosilicate glass3.3, good chemical and physical properties.

- PTFE seal, to keep high-precision sealing under poor working state.

- Japan technology AC gear reducer motor, strong torsion, no noise.

- PTFE stirring paddle is suitable for stirring and mixing different kinds of materials.

- PTFE discharge valve can discharge materials thoroughly and quick.

Types of Applications

- Boiling under reflux and coil heat exchanger distillation

- Boiling with shell and heat exchanger under reflux and distillation

- Distillation with phase separation

- Vacuum distillation

- Rectification purpose

Dimension Table

| Product Modle | AGRRC-10 | AGRRC-20 | AGRRC-30 | AGRRC-50 | AGRRC-80 | AGRRC-100 | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Volume(L) | 10 | 20 | 30 | 50 | 80 | 100 | ||||||

| Neck No. on Cover | 6 | 6 | 6 | 6 | 6 | 6 | ||||||

| External Diameter of Inner Vessel(mm) | 230 | 290 | 330 | 365 | 410 | 460 | ||||||

| External Diameter of Outer Vessel(mm) | 290 | 330 | 365 | 410 | 460 | 500 | ||||||

| Cover Diameter(mm) | 265 | 265 | 265 | 265 | 340 | 340 | ||||||

| Vessel Height(mm) | 450 | 550 | 730 | 850 | 950 | 950 | ||||||

| Motor Power(W) | 140 | 140 | 140 | 140 | 250 | 250 | ||||||

| Vacuum Degree(Mpa) | 0.098 | 0.098 | 0.098 | 0.098 | 0.098 | 0.098 | ||||||

| Rotation Speed(rpm) | 50-600 | 50-600 | 50-600 | 50-600 | 50-600 | 50-600 | ||||||

| Torque(Nm) | 2.23 | 2.23 | 2.23 | 2.23 | 3.98 | 3.98 | ||||||

| Power(V) | 220 | 220 | 220 | 220 | 220 | 220 | ||||||

| Dimension(mm) | 650x650x1900 | 700x500x200 | 700x500x210 | 700x500x230 | 1000×700×250 | 100×700×2700 | ||||||

| Materials | 3.3High borosilicate glass,0.25L-200L is optional | |||||||||||

| Receiving Flask | 3.3High borosilicate glass,1L-100L is optional | |||||||||||

| Type of Stirring | different types of stirring paddles (anchor, paddle frame, impeller etc), which can be used for the stirring and mixing of different viscosity liquid. | |||||||||||

| Condenser | 3.3High borosilicate glass,(0.3 ~3)square meters is optional | |||||||||||

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?