Product Description

Efficient gas absorption depends on the following:

- Intimate Contact

- Efficient Heat Transfer

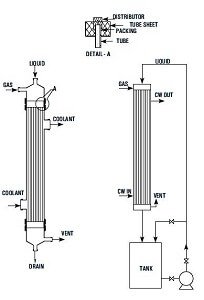

This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both gas to be absorbed and absorbing liquid flow co-currently downward with the extraction of heat by circulation of coolant in the shell. The absorbing liquid is circulated through a tank till the desired concentration is achieved. The liquid flows at such a rate that the tubes do no flow full of the liquid but instead, descends by gravity along the inner walls of the tubes as a thin film. Obviously, this produces a much greater linear velocity for a given rate flow that could be obtained if the tube flowed full.

The equipment works as a number of water cooled-wall columns in parallel and each tube is provided with distribution system on top to effect uniform distribution of both liquid and gas and also the formation of a thin liquid film on the inner surface of the tube.

Other Area of Applications

- Hydrogen Chloride Gas / Sulphur Dioxide Gas Absorption

- Hydrogen Chloride Gas / Chlorine Gas Absorption

- Hydrogen Bromide Gas absorption

- Hydrogen Chloride Gas / Chlorine Gas / Sulphur Dioxide Absorption

Salient Features

- High absorption efficiency

- High acid concentration is achievable

- Low outlet temperature

- Easy operation and maintenance

- Safe Operation due to a low isothermal temperature

- Handle a wide range of gas loading with minimum liquid flow rates to maintain full tube wetting

- Variation in Hydrogen Chloride Gas flow rates or Composition causes no operation problem.

- All the wetted parts of the falling film absorber are corrosion resistant to all the aggressive gases even at elevated temperatures

Dimension Table

| MAX. GAS ABSORPTION | MAX. ACID PROD. | ||||

|---|---|---|---|---|---|

| Nominal SIZE (mm) | Absorber AREA (m2) | No. Of Tube OD (mm) | Rate ( Pure HCL) ( kg/Hr) | Rate (As 30% HCL ) ( kg/Hr) | CAT. REF |

| 80 | 1.00 | 4/20 | 30 | 100 | AFFA3 |

| 100 | 1.76 | 7/20 | 60 | 200 | AFFA4 |

| 150 | 4.80 | 19/20 | 150 | 500 | AFFA6 |

| 225 | 7.80 | 31/20 | 250 | 833 | AFFA9 |

| 300 | 15.30 | 61/20 | 500 | 1667 | AFFA12 |

| 400 | 36.00 | 143/20 | 1175 | 3917 | AFFA16 |

| 450 | 47.00 | 187/20 | 1500 | 5000 | AFFA18 |

| 600 | 84.00 | 333/20 | 2700 | 9000 | AFFA24 |

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?