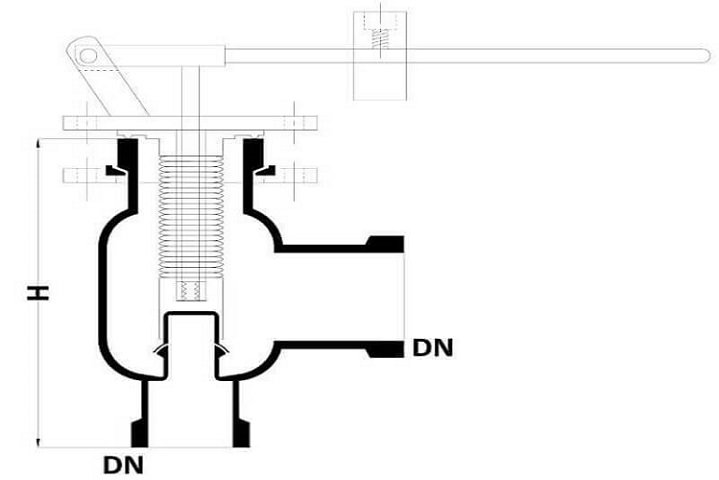

Pressure Relief Valve

A pressure Relief Valve is a safety device designed to protect a pressurized vessel or system from overpressure.

To protect the reactors & other pressurized equipment and prevent on-site accidents, ablaze has installed a Pressure Relief Valve made of Borosilicate Glass. The Glass Pressure Relief Valve is a unique valve that opens automatically when the system pressure reaches a pre-set pressure setting, partially releasing the gas/liquid and maintaining system pressure. This prevents Glass vessels and other equipment from being exposed to pressures that are higher than their design pressures.

The valve is a self-contained device that may open at preset pressure limits without the use of electricity or external control. The valve is composed of Borosilicate 3.3 glass and PTFE, and because to the chemical resistance capabilities of the materials used, it is acceptable for use with most chemicals.

The pressure relief valve is made of glass and PTFE and is actuated by weight. A PTFE bellows is used to keep moving parts sealed.

The highest suggested operating temperature is 150 degrees Celsius.

Working & Operation

A simple connection is offered for the safety of the vent as well as after each operation; the valve tends to reset itself without any labor or the material cost of a split disk replacement.

This freshly developed concept of glass pressure relief valve seat production caters to a pressure seal for the seat. The pressure on the seal will increase with the building up of the inlet pressure. The lip present can achieve this on the inner diameter of the seat that is pressing on the side of the plunger.

The pressure of the seat never gets balanced with the weight load as it has in the traditional pressure relief valves as it is not dependent on the weight load for the pressure of the seal. The physical contact between the PTFE seat and the low Friction PTFE plunger allows an easy plunger eviction from the seat at the initial pre-set pressure. Due to a sharp increase in the seat pressure, the valve gets sealed and restricts the gases as well as liquids.

The Glass Pressure Relief Valve is admirably suited to control different levels of pressure inside all types of reactors as well as the vessels where a relief valve Is needed to seal the system against both the gases as well as the liquids.

It can withstand a maximum temperature of 300°F and can take a thermal shock up to 200°F.

Pertinent Features

- High corrosion resistance qualities

- Manufactured with TFE construction and Borosilicate Glass

- High Heat resistance qualities

- Complete visibility

| Model No. | DN | Pressure Range(Bar g) |

|---|---|---|

| APSV - 015 | 15 | 0.5 - 1.0 |

| APSV - 025 | 25 | 0.5 - 1.0 |

| APSV - 040 | 40 | 0.5 - 1.0 |

| APSV - 050 | 50 | 0.5 - 1.0 |

Benefits of Glass pressure relief valves

- It is entirely corrosion-resistant.

- It is made up of TFE and Borosilicate Glass.

- It has high heat resistance qualities.

- It’s patented seal ensures a better seal functioning against all types of liquids and gases.

- It comes with clear transparency or visibility for you to inspect.

- It bears no replacement cost as the valve resets itself.

- It has no stuffing box to maintain.

Final Thoughts

The Ablaze Export PTFE pressure relief valves were manufactured to use on the systems that require the corrosion resistance ability possessed by PTFE. The operating principle remains constant as priorly used in the regular line of the Safety Pressure Relief Valves having corrosion resistance qualities made from the borosilicate glass.

Ablaze Export glass pressure relief valves have the corrosion-resistant qualities against all liquids as well as gases other than the hydrofluoric acid and the hot concentrated caustics. The Ablaze Export Pvt. Ltd. assures a perfect seal against all our manufactured equipment, as well as liquids and gases.

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?